It’s the print and packaging equivalent of Your vs. You’re.

Don’t worry. We’re here to help you clarify this conundrum!

Do you want your graphics embossed or debossed? The terms sound similar but have very different meanings. In fact, they’re complete opposites.

We get the emboss vs. deboss question regularly in project consultations with designers and brand managers alike. It’s understandable; this isn’t a topic that usually comes up in daily conversations, unless you’re a print devotee. Material decoration is at the core of a successful dimensional brand presentation, which is what we are all about at Pusterla .

As your packaging experts, we would like to settle matters.

Let’s take a look at:

1.) How to tell the difference

2.) When it’s best to use one technique or the other

3.) How Emboss vs. Deboss can affect the bottom line.

(editor’s note: deboss does not mean you can lock your boss in a broom closet until the project is complete!)

What makes this so complicated?

Well, mainly that the two words sound essentially the same but mean the opposite of one another. Here’s the breakdown:

DEBOSS = DEPRESSED.

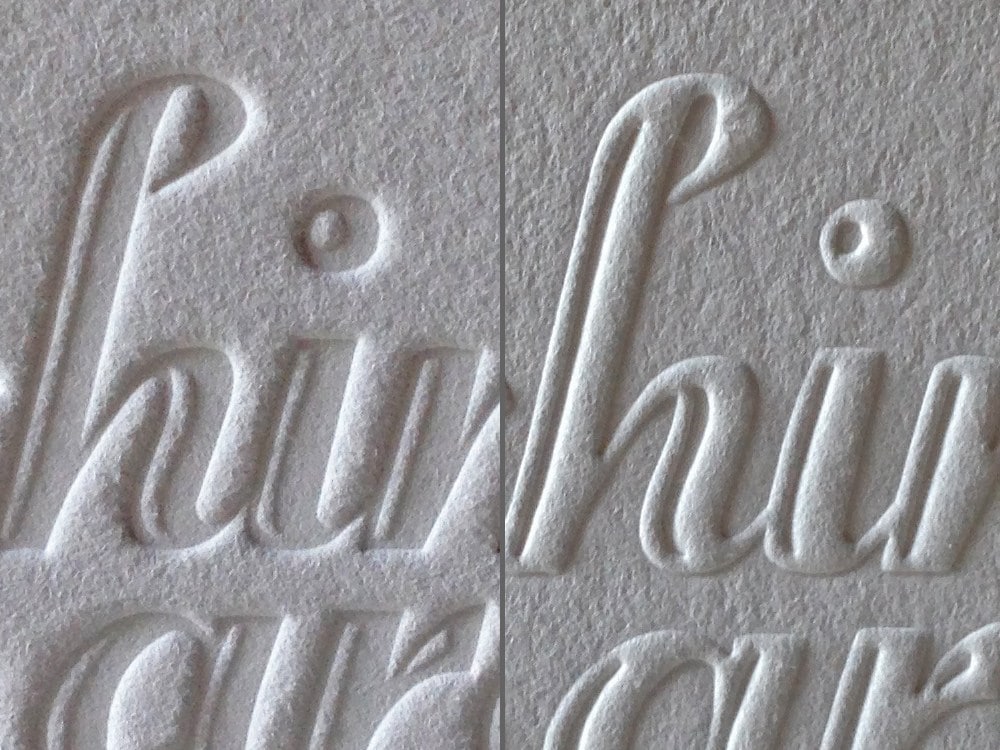

No, debossed is not sad ☹. Debossed is a lowered, or sunken, area in your print design. This means your graphics will be pressed into the substrate you are stamping. If you can remember that, you’re golden. Just know that EMBOSS is the opposite, and therefore raised⎯ the graphics will jut out from the substrate.

Why one or the other?

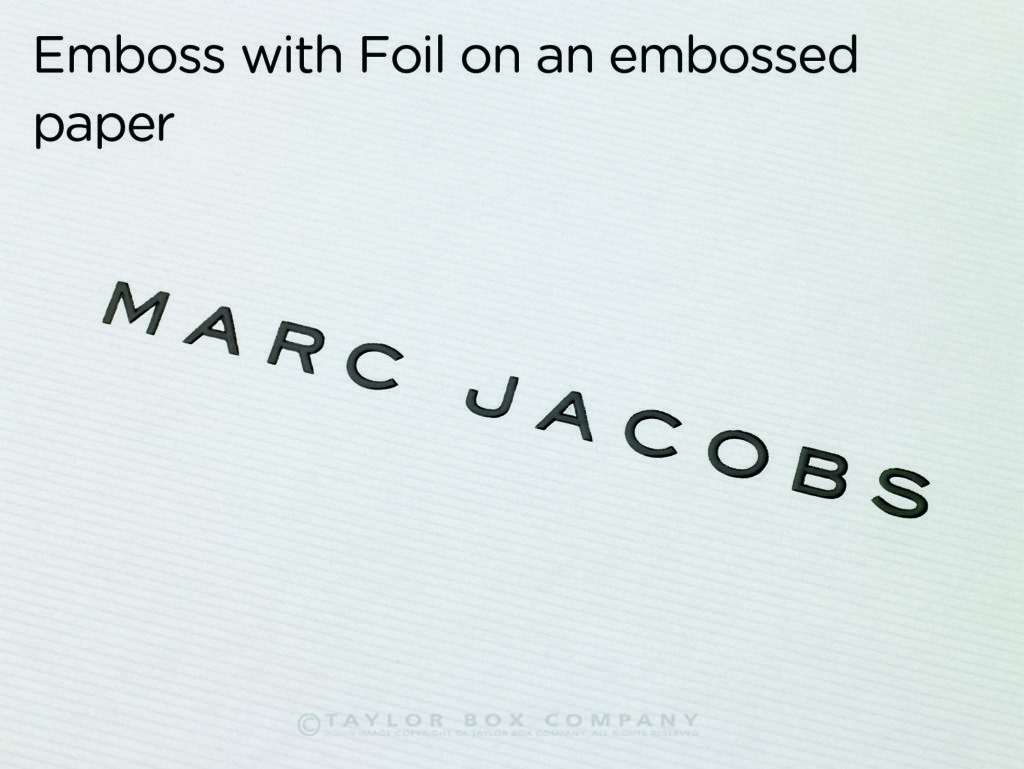

Debossing is usually done in conjunction with a foil stamp, called a ‘combo’. The end result will look something like traditional letterpress; a recessed area filled with a shiny or matte color.

You can also opt to deboss without a foil, which is referred to as a ‘blind deboss’. This style is very popular on solid color premium wrap materials, like soft touch coated stock or linen book cloth, for that sleek, monochromatic effect.

*Pro-tip: if you want the blind deboss look but are afraid it will make your graphics illegible, ask us to sample your cover material with a clear foil combo hot stamp/deboss. The little bit of sheen will help distinguish your lines.

Embossing is one of the most premium looking effects, and an excellent choice if you have a particularly antique design, or want to add a dimensional and tactile experience to your graphics. Even without color, a thick or cotton fiber stock paper will create a rich, clear emboss. Alternatively, when combined with a metallic or colored foil, an embossed design will look like a convincing seal.

*Pro-tip: new developments in printing mean there are alternative methods to mechanical embossing for a tactile decoration. Introducing raised UV printing; a special high-viscosity UV ink is applied over your substrate and produces a high gloss beautiful embossed effect.

Why the difference in price?

Both embossing and debossing require the fabrication of a metal plate. However, embossing requires an additional metal element called a counter (to push the material into the metal plate). This means a higher set-up cost, which may impact your unit cost considerably if you are looking for a small run of boxes.

That said, if a particularly deep deboss is desired, or if you want to deboss a box wrapped in a thin cover material, the deboss must happen after the box is wrapped. This style of production requires a hand-operated machine and a custom wood block to support the box.

In conclusion: if budget is essential to a project, your quantity and materials will determine which method is more economical. If aesthetic and design are at the wheel, try both!

Contact us today to get started on your beautifully printed box, or consult our experts on a packaging project!