It’s finally summer! Here in Rhode Island, we’ve put away our parkas and swapped our snow boots for sandals. After months of being cooped up indoors, we’re rediscovering the pleasures of fresh air and outdoor activities. But now, we have to contend with the heat and humidity.

Luckily, there’s plenty of ways to beat the heat in the Ocean State. The beach is never far away and there’s no shortage of refreshing cold beverages at our disposal (coffee milk, anyone?). But does anything beat a scoop of cold ice cream on a hot summer day? No way. Not in Rhode Island, not anywhere else.

This month, we’re looking at a phenomenal sales kit for Magnum Ice Cream, developed to introduce their new line of Magnum Tubs.

Magnum is famous for their premium chocolate-covered ice cream bars. The brand prides itself on sourcing quality, Rainforest Alliance certified chocolate and vanilla, among other ingredients. The impeccable crack of their smooth chocolate shell in combination with lush ice cream makes for an irresistible confectionery experience. But Magnum was looking to expand their product offerings beyond the bar, and needed a distinguished packaging design to launch their latest foray into frozen treats; Magnum Tubs, which have all the trappings of a Magnum ice cream bar remixed into an interactive ice cream pint.

We collaborated with Printing Arts to create a custom packaging experience that exemplified the character of Magnum while celebrating the inventiveness of Magnum Tubs. And before you get ahead of us – yes, there was real, cold Magnum ice cream contained in the box.

Beyond a delicious ice cream base, Magnum’s claim to fame is their luxurious chocolate, used to create a hardened shell on the outside of Magnum ice cream bars. Incidentally, there’s a certain chocolately-ness to the appearance of the box. A deep, earthy tone surrounds the box in brown Mano paper from Neenah. The combination foil stamp and debossing of the Magnum logo on the outside panel immediately invites us in, reassuring us of the quality contents of the box.

This sales kit was engineered to perfectly demonstrate the fun, engaging, and delicious Magnum Tubs. Printing Arts was responsible for the brilliant packaging design, while Pusterla was behind the manufacturing process. Included in the kit was a pint of Magnum’s chocolate-covered ice cream, but also a gold spoon and an hourglass timer.

To amplify the impact of revealing the brand new product, a specially commissioned sheet of chocolate embellished with the Magnum logo was overlaid on top of the pint Magnum Tubs. Breaking through a chocolate shell is paramount to the experience of enjoying the product itself, and accordingly, cracking the chocolate shell in the box is integral to the packaging experience. This clever concept demonstrates the novelty of the product and establishes the mood for the ensuing sales presentation.

An hourglass was included to measure the optimum temperature of the ice cream after the outer shell is broken. As the spoon breaches a solid layer of chocolate at the top of the container with a magnificent *crunch*, the hourglass is activated to time just the right amount of melting as the chocolate and ice cream mingle.

When dealing with ice cream, there needs to be a certain assurance that the product stays frozen. So, an oversize foam insert was engineered not only to hold the collateral in place, but to insulate the product and maintain optimal temperature. Thick, durable Eskaboard comprises the material structure of the box, providing not only a reliable rigid construction, but a final level of insulation for that coveted ice cream.

The insert was developed as the key feature of the box. Black flocked foam gives a velvety texture to the interior, indicative of the premium product it holds. Besides the sheer amount of foam used for insulation purposes, each of the designated collateral areas were die-cut for ease and efficiency of removal. Notice the thumb cuts on either side of the spoon and the hourglass.

Premium magnet closures provide a touchpoint of assurance on the packaging journey. Ensuring a tight seal, the magnets give a sense of security as well as luxury. The resistance of opening the box might come as a surprise, after all, we expect a box to open with minimal effort, but the addition of magnets immediately indicates that this is another class of packaging, beyond the average box.

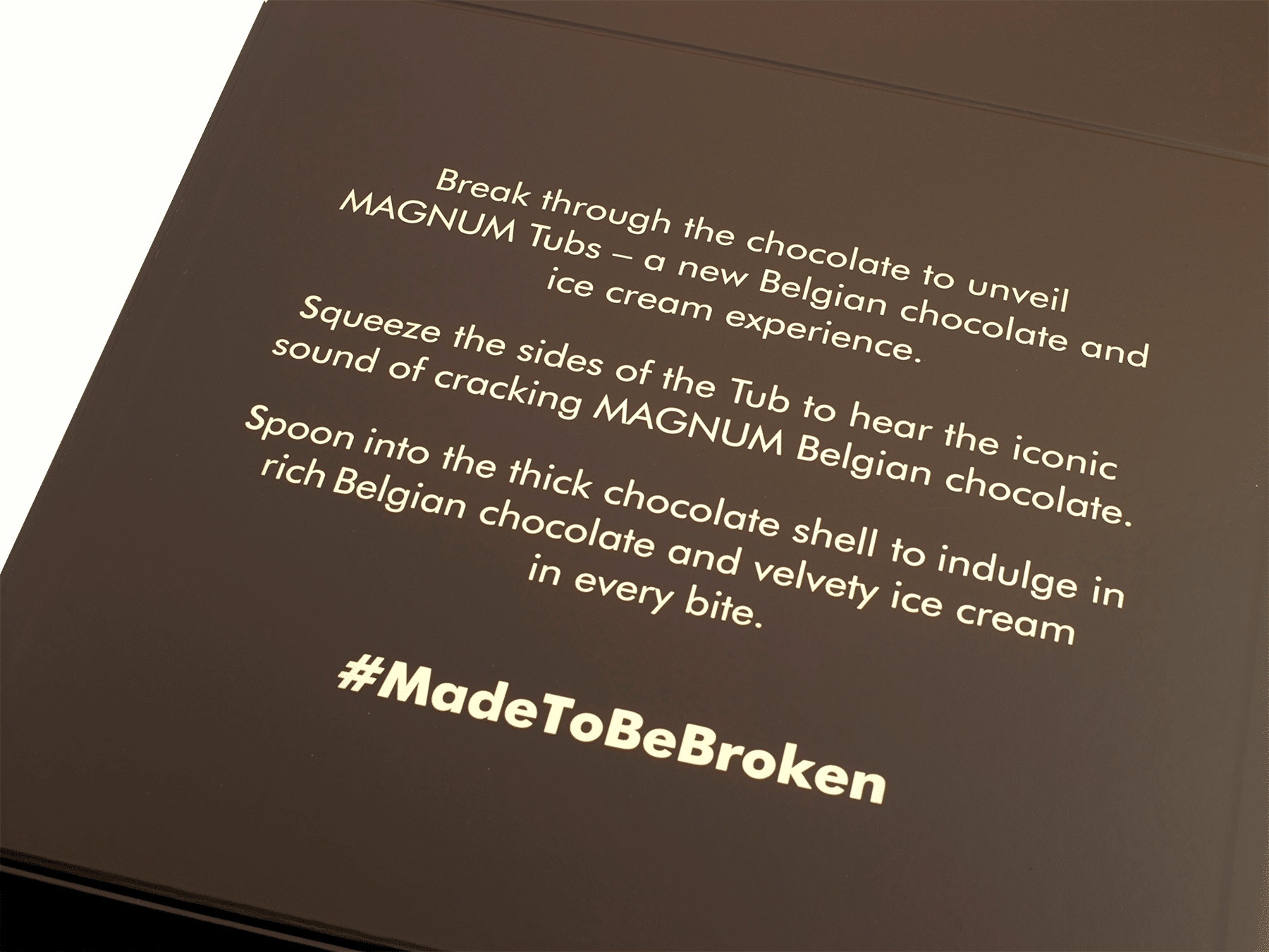

On the reverse side of the lid is an instructional from the folks at Magnum, punctuated with the hashtag #MadeToBeBroken. Gold foil stamping to match the decoration on the outside panel heightens the high end sensibilities of the packaging. The simple addition of a branded message in artisan foilwork gives a far different sensation than if the message were rendered in digitally printed ink. Every letter, every character shimmers, adding a dynamic element to the copy that print doesn’t necessarily afford.

Also, consider the intricate, precision work involved with foil stamping such a large volume of fine lettering. Getting every word and phrase perfectly treated with the right amount of gold foil was no small task, involving multiple adjustments to properly distribute pressure and heat across each panel.

This sales kit represents the possibilities of custom packaging. Paperboard is an incredibly versatile material, able to adapt to the packaging needs of a wide variety of markets. Frozen confections aren’t the first thing that comes to mind when we think of rigid boxes, but with a little finessing (or a lot of clever design) a premium product like Magnum Tubs is suited perfectly for paperboard.

Is custom packaging a must for your next project? Get in touch with us today!